Precision Regulation and Control: The Heartbeat of Industrial Manufacturing

Tags: Control, Manufacturing, PC Boards,

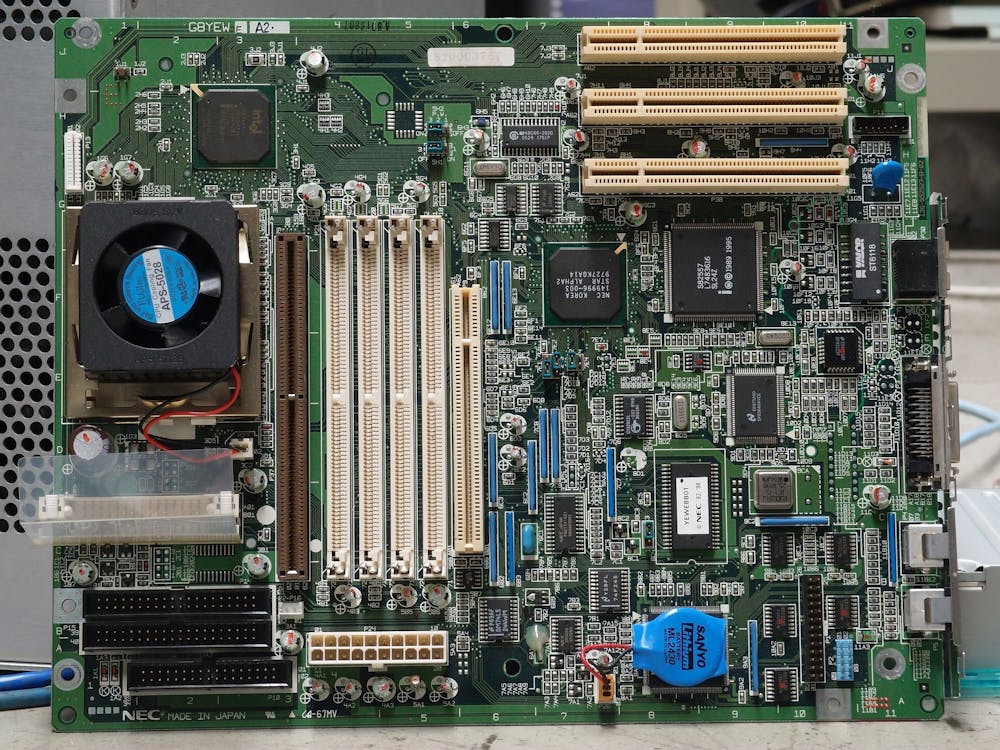

In the complex world of industrial manufacturing, precision regulation and control are paramount to ensuring efficiency, quality, and safety. The incorporation of PC regulator assembly boards into manufacturing systems has become a critical factor in achieving this precision. These boards play a vital role in regulating and controlling various aspects of the manufacturing process, from the operation of machinery to the management of entire production lines.

The Necessity of Precision in Industrial Manufacturing

Industrial manufacturing processes often involve the handling of materials and operation of machinery under stringent conditions. Precision in these processes is crucial for several reasons:

-

Ensuring Product Quality and Consistency

Precision regulation and control are essential in maintaining the quality and consistency of products. In industries like automotive manufacturing or electronics assembly, even the slightest deviation can lead to product defects, resulting in increased waste and cost.

-

Optimizing Efficiency and Productivity

Accurate control of manufacturing processes leads to optimized efficiency and productivity. Precisely regulated machinery operates at optimal levels, reducing wear and tear, minimizing downtime, and enhancing output.

-

Safety and Compliance

In many manufacturing settings, safety is a primary concern. Precision control helps ensure that machinery and processes operate within safe parameters, protecting both the workforce and the environment. Additionally, many industries have strict regulatory standards that can only be met through precise control mechanisms.

The Role of PC Regulator Assembly Boards in Manufacturing

PC regulator assembly boards are specialized components designed to manage and regulate the operation of machinery in manufacturing settings. These boards are integral to the precision control systems of modern manufacturing facilities.

One of the primary functions of PC regulator assembly boards is the regulation of motor speed and torque. In applications like conveyor belts, mixers, or pumps, these boards ensure that motors operate at the precise speed necessary for the task, leading to consistent product quality and efficient use of energy.

In automated manufacturing processes, PC regulator assembly boards are crucial for controlling various stages of production. They synchronize operations, ensuring that each component of the manufacturing line works in harmony with others. This synchronization is key in complex manufacturing processes where timing and coordination are essential.

Modern PC regulator assembly boards offer a high degree of adaptability and can be programmed to meet specific manufacturing needs. This flexibility allows manufacturers to quickly adjust their processes in response to changes in production demands or to accommodate different products.

Advancements in PC Regulator Technology

The field of PC regulator assembly boards has seen significant advancements over the years, driven by the evolving needs of industrial manufacturing.

Integration with Digital Systems

The integration of digital technologies with PC regulator assembly boards has enhanced their functionality. Modern boards can be connected to computer systems, allowing for more sophisticated control algorithms and real-time data analysis. This integration enables predictive maintenance, process optimization, and enhanced quality control.

Miniaturization and Efficiency

As manufacturing processes become more complex and space becomes a premium, the miniaturization of PC regulator assembly boards has become important. Smaller boards save space while maintaining or enhancing functionality. Additionally, advancements in electronics have led to more energy-efficient designs, contributing to the overall sustainability of manufacturing operations.

Enhanced Communication and Connectivity

The ability of PC regulator assembly boards to communicate with other systems and devices has been a game-changer. With technologies like the Internet of Things (IoT), these boards can now be part of a larger, interconnected system, enhancing the efficiency and intelligence of manufacturing processes.

Conclusion

Precision regulation and control are the lifeblood of modern industrial manufacturing, ensuring that products are made efficiently, safely, and to the highest quality standards. PC regulator assembly boards are at the forefront of this precision, providing the control and regulation necessary for complex manufacturing processes. As manufacturing continues to evolve and embrace new technologies, the importance of these boards in maintaining precision and driving innovation will only increase, solidifying their role as a cornerstone of industrial manufacturing.